|

From prehistoric

times Cornwall's rich supply of tin and copper attracted many prospectors

and workers to the region.

Early man

would barter pottery, salt, and cloth in return for tin and lead from

Cornwall. This signified the beginning of a long and turbulent history

of tin mining in the South West.

Humble

beginnings

|

|

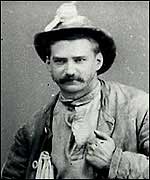

Early

tin miner with tallow candles around his neck |

From the

early settlers who arrived in Cornwall from Europe around 2300 BC, to

the later half of the 17th Century, Cornish mining was largely limited

to surface mining.

Developments

towards the end of the 17th Century saw the introduction of gunpowder

in the process of mining.

Controlled explosions helped in breaking up the rock and further increased

mining prosperity.

But shallow mining was to soon be replaced by deep rock mining underground.

Rich

Pickings

But it wasn't

until the 18th Century and the invention of machine driven pumps, that

Cornish tin mining became a capitalist concern.

Mine

shafts inevitably dropped below water level, so prior to this date, shallow

mining was the only way to extract the tin and copper from the ground.

The machine

driven pump was powered by steam engine and was capable of lifting several

gallons of water per minute from great depths.

In 1710,

the first steam driven water pump was installed in Cornwall, allowing

deep mining to take place for the first time.

These pumps

were so successful that the output of tin and copper rose prodigiously

and Cornwall became the home of deep mining.

On the

up

|

|

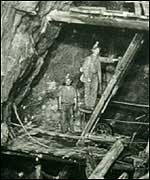

Conditions

below ground were often dangerous |

The introduction

of the steam driven pump was a turning point for Cornish mining.

By 1801 there were 75 mines employing around 16,000 people in Cornwall.

In 1819

the two major mining groups Great Consolidated and United were created.

John Taylor, one of Cornwall's greatest mining engineers, managed both

groups which together produced thousands of tons ore.

The mined

ore was sent down the Redruth and Chasewater railway for shipping around

the world at Devoran and Restronguent Creek.

From boom to bust

Cornish

tin mining reached its zenith in the 19th Century.

|

|

A

bleak future for tin |

By 1862

Consols and United had merged to form Clifford Amalgamated mines and there

were around 346 mines in Cornwall, with a working population of 50,000.

Despite

the collapse of the copper mining industry in 1866, the tin industry was

still riding high producing 10,000 tonnes of tin a year - about half the

world's production.

But such

success was short lived.

During the 20th century tin mining was characterised by cycles of boom

and bust.

There is

a saying, what goes up, must come down, and in a few short years Cornish

tin mining - like its mines - was about to learn just how far down it

could go.

Timeline

1700BC-1400BC

- Earliest Cornish tin mines

1919 - Levant

Mine Disaster

1985 - Tin

prices plummet on the Tin Exchange

1986 - Closure

of Geevor Mine in Cornwall

1998 - South

Crofty is the last Cornish tin mine to close

|